News

LATINGALVA 2021

Ahora virtual / Now online

Noviembre/November 15-17, 2021

In light of the concerns in relation to Covid-19, LATINGALVA 2021 will be held online. Registration will open during the month of September.

The next regular in person event will take place in fall 2023.

LATINGALVA is the leading international conference and exhibition on hot dip galvanizing in Latin America. It provides a unique platform for companies from around the world to exchange information on the latest advances in technology and operating processes, environmental regulations, best practices and market trends. The conference is complemented by an exhibition of international equipment and service suppliers, plant visits and social activities.

LATINGALVA is targeted at general galvanizing managers and engineers, designers of infrastructure projects, architects, others involved in general construction, suppliers to the industry, as well as public officers involved in infrastructure and public work development.

The conference will be held in Spanish with simultaneous interpretation into English.

Registration will open during September 2021

Contact

Berit Wirths

Communications Manager

International Zinc Association

Email: bwirths@zinc.org

Debido a la situación frente al Covid-19, LATINGALVA 2021 se celebrará de forma 'online'. Las inscripciones se abrirán durante el mes de Septiembre.

El próximo evento en persona tendrá lugar en el otoño de 2023.

LATINGALVA es la conferencia y exposición internacional más importante sobre el tema del Galvanizado por Inmersión en Caliente en Latinoamérica. Proporciona una plataforma única para empresas de todo el mundo para intercambiar información sobre los últimos avances en tecnología y procesos operativos, modificaciones en las normativas ambientales, buenas prácticas y tendencias del mercado. La conferencia se complementa con una exposición de proveedores internacionales de equipamiento y servicios, visitas a plantas de galvanizado y actividades sociales.

LATINGALVA se dirige a gerentes e ingenieros de la industria del galvanizado, diseñadores de proyectos de infraestructura, arquitectos, otras personas involucradas en construcciones generales, proveedores de la industria, así como los funcionarios públicos involucrados en el desarrollo de infraestructura y obra pública,

Apertura de inscripciones: durante el mes de Septiembre 2021

Contacto

Savio Cé

IZA Latinoamérica

Email: sce@zinc.org

Climate Change

Mine Tailings and Residue Management

Managing Minor Elements

Environmental Management

Mine Closure

Sustainability Reporting

Children’s Rights in the Workplace

Business Ethics

Product Stewardship

Employee Health & Safety

Community Consultation

Sustainability Charter

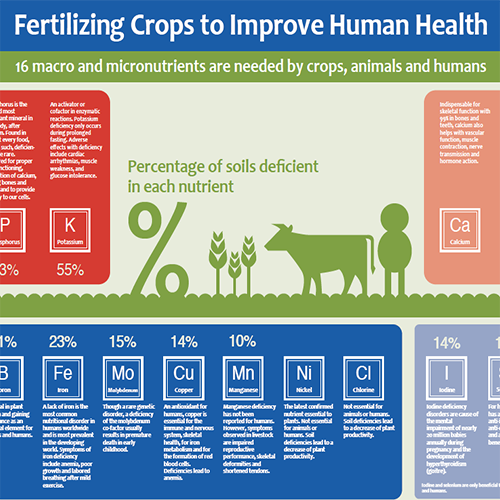

16 Nutrients Required for Healthy Crops

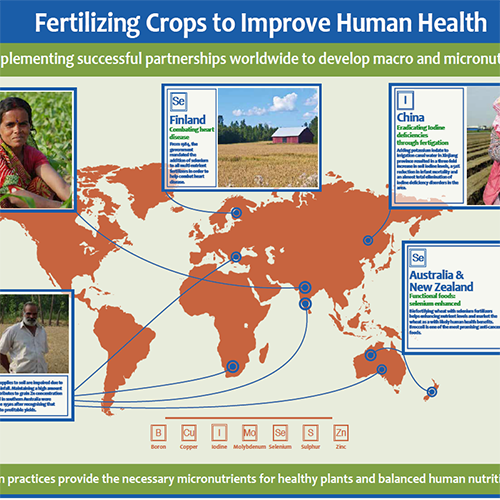

Countries Practicing Successful Fertilizer Use

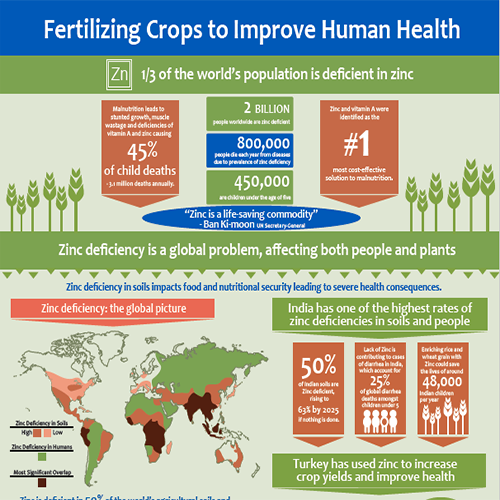

Zinc in Crops

Rice Factsheet

Sugarcane

Wheat Factsheet

Maize

Zn Fertilizer and the Environment

Zinc Fertilizer Options

Zinc Fertilizer Overview

Why Zinc Die Castings?

The die casting process is a forming process in which molten metal is injected into the cavity of a steel die. The cavity is precision machined, with tight tolerances, into a block of heat resistant tool steel. Coupled with process control and the uniform shrinkage characteristics of zinc alloys, this process results in castings with exact precision.

McCann Health Joins “Call to Action on Child Survival”

Learn about the basic need of Zinc by children around the world. Learn how we all play a part in saving children's lives.

[video_embed][/video_embed]

Ultra Thin Zinc Die Casting Alloys

This publication presents the main characteristics of the recently developed High Fluidity (HF) Alloy that is based on the traditional Zamak composition and the earlier developed copper-rich alloy marketed under the names of Superloy and GDSL.

Hot Dip Galvanizing in Mining

This publication covers galvanized components in surface projects, underground mines, conveyors and marine terminals. Also included are over 20 case studies of general galvanized structural components used in mines throughout the world.

Continuous Galvanized Rebar: An Introduction

This brochure describes the process of continuously galvanizing rebar and features its unique advantages including coating adhesion, corrosion resistance, ease of coating and cost savings.

A Performance Evaluation of Traditional and Green Surface Finishes for Zinc Die Castings

This 12–page publication provides the performance results of a series of new surface finishes using best practice green technology that was tested in two categories – corrosion protection and aesthetic retention – and compares them to the results of an earlier study conducted with traditional surface finishes.

The New High Fluidity Zinc Alloy

This brochure was created on behalf of the U.S. Department of Energy and the North American Die Casting Association to illustrate the properties of a new high fluidity zinc alloy.